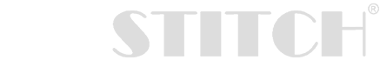

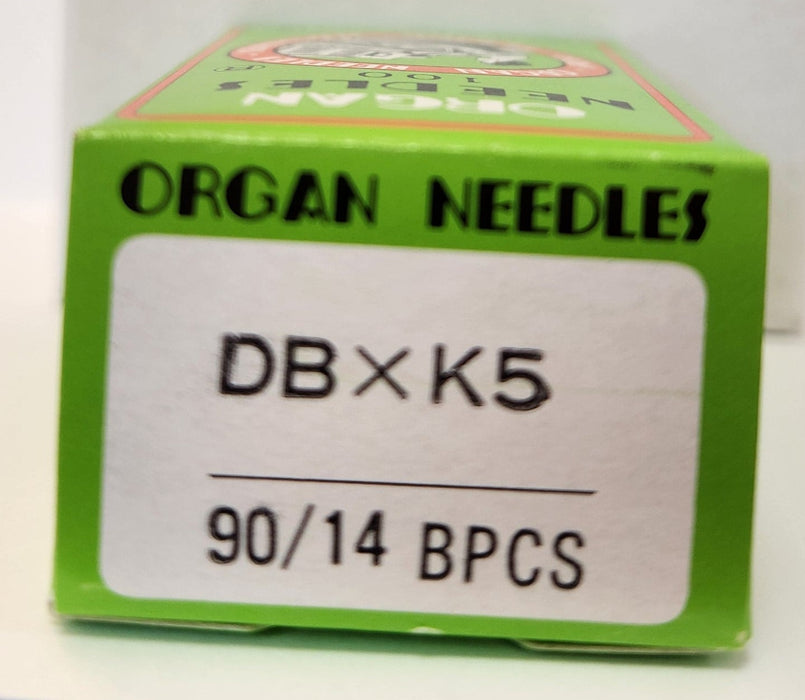

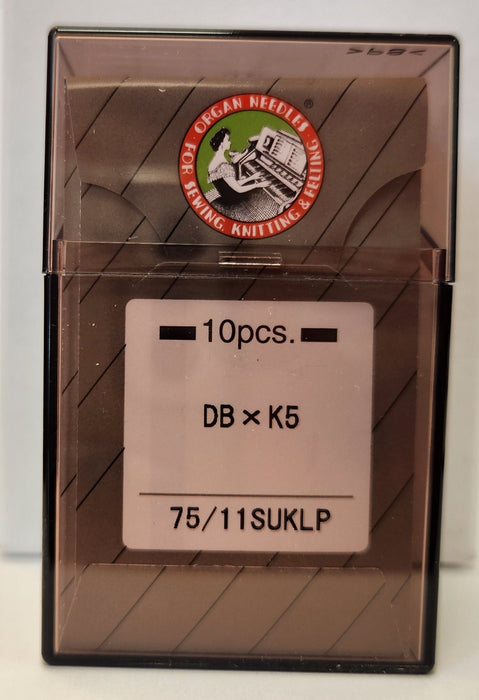

Organ DBK5BPLP | Round Shank | Large Eye | Ball Point | Commercial Embroidery Needle | LP (COOL-SEW) | 100/bx

These ball point, commercial embroidery needle has a special coating (LP/COOL-SEW) that prevents glues and spay adhesives from sticking to the the needle while embroidering.

The COOL-SEW finish creates a "non-stick" surface on the needle and inside the needles eye. It is intended to alleviate many problems that arise from using synthetic threads and synthetic materials. Synthetics can heat up and stick to the needle surface to some degree more or less. These problems may also be found with certain chemically treated and dyed fabrics

As synthetic threads pass through the eye of the needle they create friction and heat which may melt or snap threads. In some cases, they eye of the needle may be cut. The COOL-SEW finished needle eye acts as if the eye is lubricated and thereby alleviate aforementioned problems.

As an ordinary chromium plated needle penetrates through synthetic materials, the materials may stick to the needle. This may cause some of the synthetic materials to pass through the needle holes and create undesirable finishes. Stabilizers can also attach themselves to the sticky needle and pull up to the surface. The sticking to the surface of the needle may also create heat build up problems. Such as melting and machine jam ups. The COOL-SEW finish on the needle helps to alleviate the sticking and heat build up problems.

- Organ DBK5LP-CS Commercial Embroidery Needle

- LP Coating - COOL-SEW

- Commercial Round Shank

- DBxK5 - Large Eye

- SUK/BP - Medium Ball Point

- 100 Needles Per Box

Organ Round Shank Commercial Needles -100 Needles/Box

DBxK5 CS Cool Sew Teflon Coated Non-Stick Needles - Ball Point

DB-K5 CS: The Cool-Sew finish was developed to alleviate needle problems resulting from the following situations:

- Heat Buildup in penetration of synthetic, chemically treated, or very dense materials.

- Materials or residue sticking to needle surface or in eye.

- Excessive sewing thread breakage due to friction in the needle eye.

The COOL-SEW finish needle surfaces, even in the eye, are resistant to sticking. Its non-stick finish has a very low friction coefficient which prevents excessive heat buildup and its resulting problems. Few, if any, materials stick to the surfaces of Cool-Sew needles. When COOL-SEW needles are used under conditions described above you can expect neater stitches, less sewing thread breakage, less puckered stitches, less downtime, less defects, and increased productivity. COOL-SEW needles are ideal for sewing through vinyl, synthetics, chemically treated materials, glued materials, rubberized goods, nylon, foam, dense materials, and with synthetic threads. As a needle penetrates synthetic, chemically treated or very dense materials a great deal of friction may develop. The needle may get so hot as to actually melt or fuse the sewn material along the seam. The needle heat may melt the synthetic sewing thread. When the machine stops, the melted residue may stick to the needle surfaces as it cools. The nature of some materials makes them rather “sticky" Materials such as rubber, foam, and synthetic fillers stick to surfaces with which they make contact. They may stick to needles which penetrate through them, even at relatively slow sewing speeds. The result may cause undesirable stitch appearances as these materials push through or pull up through needle holes. Synthetic threads often have a higher friction coefficient than natural fiber threads such as cotton. Passing through the eye of a needle friction develops which causes the needle to heat up. As the speed of the thread passing through the eye of the needle increases, the heat of the needles rises, often to temperatures which will melt the synthetic sewing thread causing it to break. ‚ Chemical coatings or treatments of threads and materials may cause troublesome sewing problems. Bonded layers, waterproofing, dyes, starches, adhesives, sizings, or other alterations to any fibers may result in needle heat-buildup, sticking problems, excessive thread breakage, and clogged needle eyes.

Ball Point: Ball point machine embroidery needles are designed to alleviate making holes in knit or loosely woven materials. The cross fibers which constitute the knit or loosely woven materials are relatively far apart as compared to those in tightly woven materials. When an embroidery needle with a standard "set" or "sharp" point encounters one of those fibers in penetrating the fabric, it cuts right through the fiber. This creates a hole in the fabric. The ball point needle pushes aside the fiber it encounters in penetration and thereby avoids making a damaging hole in the fabric. (It is also recommended to use the thinnest possible needle for a particular fabric).