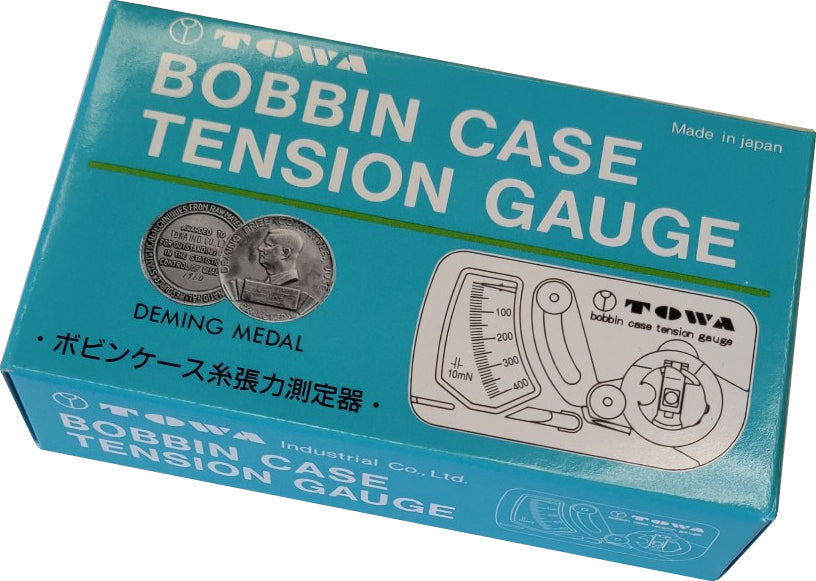

Towa Bobbin Case Tension Gauge - TM-1 Style L

Regular Size Bobbin Case Gauge for Commercial Style L Bobbin Cases

With the Towa Bobbin Case Tension Gauge the guesswork is gone forever. This bobbin tension gauge allows embroiderers to consistently measure and set accurate embroidery bobbin case tension. In just a few seconds you can verify your bobbin tension is where it should be to achieve optimum results. It's simple to use and comes with complete instructions. No setup is required. It's ready to use right out of the box. Measures tension from 10mN to 400mN

How to Use a Bobbin Tension Gauge Take the guesswork out of setting thread tensions. Using thread tension gauges makes it easy to adjust both bobbin and upper tensions. It's quick, easy and will help you eliminate unsightly bobbin thread showing on top, looping top stitches and thread breaks. Your embroidery will look its best with consistent, balanced thread tensions. Here's how to use a bobbin tension gauge to take the tension out of setting tensions!

Instructions for Use:

- Remove the bobbin case from your machine. Be sure the bobbin thread is out of the pigtail and place your bobbin case with the bobbin in it into the gauge slot. Snap the bobbin case in place.

- Wrap the bobbin thread around the two pulley wheels and around the plastic hook end on the gauge.

- Steadily pull the thread and note the reading on the gauge. This represents tension readings in grams. Correct bobbin tensions should be 180 to 220 grams (up to 250 grams when embroidering caps).‚ Please Note: If your gauge is shown in units of 10's, the correct bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps.)

- Adjust the bobbin case spring tension screw as needed to get the desired reading.

Note: The gauge needle should provide a steady reading. If you experience a bouncing, erratic reading it can be due to a dirty or defective bobbin case

Tip: Slide a business card back and forth under the bobbin tension spring to clear any dirt.

Once you have adjusted your thread tensions, it's always a good idea to run tests.

- First run‚ a fill stitch test pattern.

- If you experience any top stitch looping, slowly tighten the main upper tension knob until this looping goes away (looping can also occur if your bobbin tension is too tight).

- Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread color on the underside of the embroidery.