Get help

Browse our collection of educational articles.

Choosing the correct needle for your embroidery machine is crucial to ensuring your machine correctly stitches out your design. There are 100's of different types of needles, points, finishes and styles to choose from making what kind of needle is best to use one of the most confusing topics for those starting out in embroidery.

Flat Shank Vs. Round Shank?

The first thing you need to know is if your machine uses a flat shank or round shank needle. The shank is the top part of the needle that inserts into your machine. Single needle home machines as well as the Brother and Baby Lock 6 & 10 needle machines use flat shank home needles. Industrial machines like Tajima, Barudan, Melco and others, use round shank commercial needles. Flat shank needles usually (but not always) start with 15x1, and round shank usually starts with DBxK5.

Ball Point or Sharp?

Needles come with various shapes of points or tips. The two most common are ball point and sharp. Ball point needles are designed to alleviate making holes in knits or loosely woven materials. A sharp, or standard point needle is used for tightly woven fabrics, quilt cottons or special applications.

How Do I Know What Size Needle I Need?

Needles sizes are designated by 2 different numbers, one is the American measurement and the other is the European, and refer to the diameter of the needle shaft. Sizes are usually presented as 2 numbers, such as 11/75, with the European size as 75 and American size as 11. The lower the number the smaller the needle diameter and the smaller the eye. Smaller size needles should be used for lighter weight fabric and/or lighter threads.

Larger needles should be used for heavier fabrics and/or thicker threads. You should always use the smallest size needle that is appropriate for the fabric. If unsure, start with the smallest size needle you think will work, and then move up in size if needed. Using a smaller needle, means smaller holes in your fabrics and will help you keep the correct tension. Using too big of a needle size can cause too large of a hole in the fabric, resulting in excess play of the thread which can cause looping or loose tension.

What about Titanium Needles, are they Worth It?

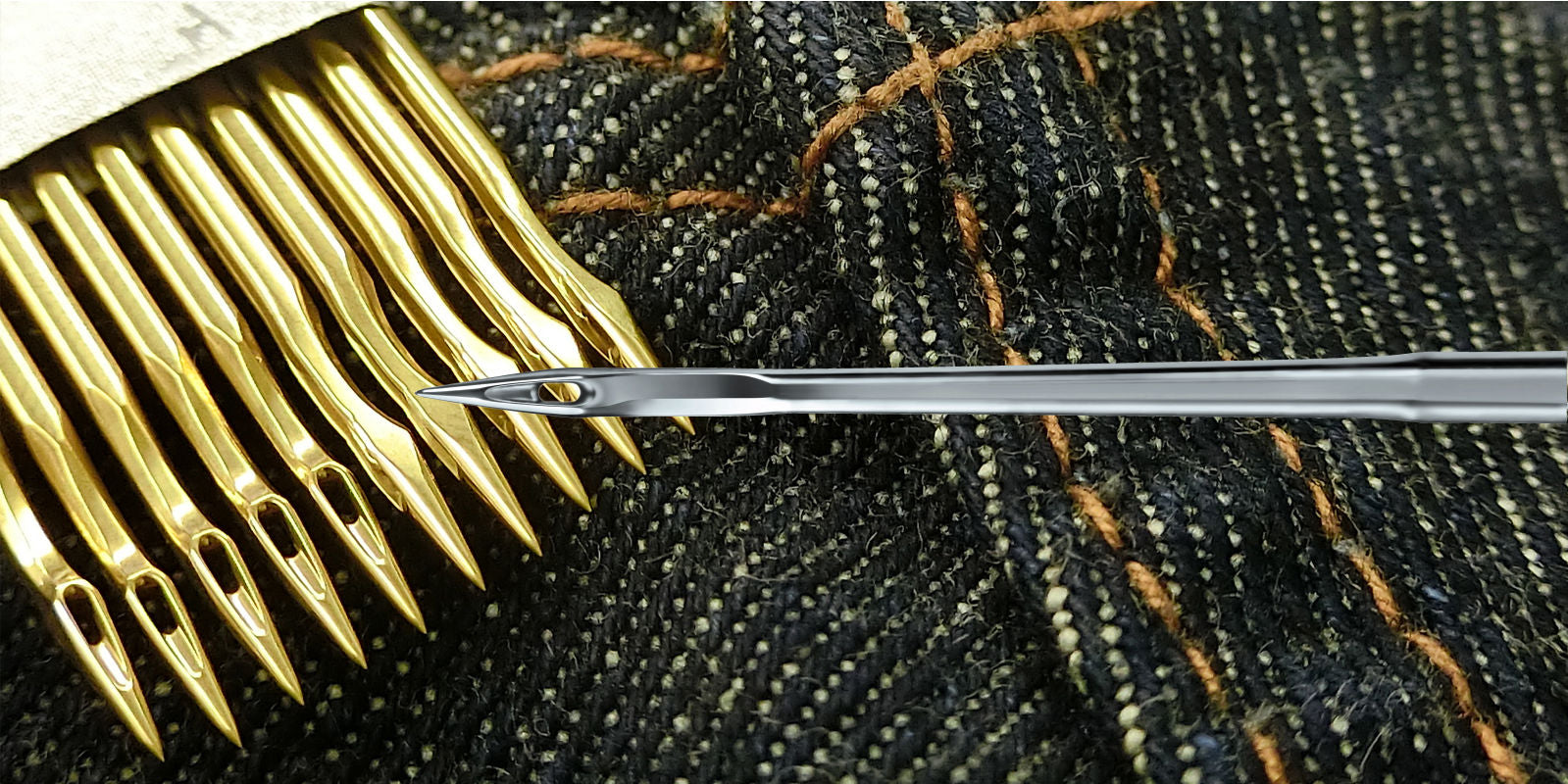

Needles come in several finishes, with the most common being Chromium. These are great all around needles and can be used for most sewing and embroidery. It's recommend they be changed after 5-10 hours of sewing depending on the type of thread being used and the fabric being embroidered on. Titanium (PD) gold needles have a titanium-nitride ceramic finish which makes them more wear-resistant than other needles.

Titanium needles also can run cooler than regular needles, reducing chance of needle and thread breakage. When embroidering large stitch patterns or penetrating very abrasive, dense or tough fabrics, titanium needle points and surface will maintain its original shape and dimensions 3 to 5 times longer. PD needle points will not wear down as fast as chromium plated needle points. The use of PD needles gives you longer needle life, fewer defects due to "dulled" needle points, and increased productivity.

~~~~~~~~~~

Now that you have read the basics of embroidery needles, if you want to dive in deeper to the different kinds of needles and sizes available,

Click Here To Consult our Needle Selection Guide

Comments

Leave a comment